- Steel Wire Mesh[10]

- Corner Guards[3]

- Iron Wire Mesh[10]

- Stainless Steel Wire[9]

- Iron Wire[10]

- Nails[7]

- Steel Wire[3]

- Barbed Wire[10]

- Steel Sheets[4]

- Metal Building Materials[9]

- Fencing[10]

- Door & Window Screens[2]

- Fiberglass Mesh[5]

- Shade Sails & Nets[3]

- Other Heat Insulation Materials[3]

- Steel Structures[3]

- Agricultural Plastic Products[1]

- Conveyors[2]

- Screens & Room Dividers[3]

- Contact Person : Ms. Wang Tracy

- Company Name : Anping Yuze Hardware Wire Mesh Co., Ltd.

- Tel : 86-311-67906100

- Fax : 86-311-67906101

- Address : Hebei,Anping county,No.5 Zongzhuang Industrial

- Country/Region : China

- Zip : 053600

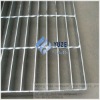

Steel Galvanized Grating

Galvanized Steel Grating

The fence is made of steel grating and steel.It has the characteristics of firmness,the momentum is grandiosity,gentle and cultivated,unique style.It was used in municipals,garden,park,traffic,architecture,ditch lid.

Our Policy:

1. Customer care is our top Priority 2. Good Quality is our Mission 3. High Efficiency is our Goal 4. Pursue Constant Innovation is our Task

Serrated Steel Grating is done for slip resistance. Serrated Steel Grating is grating which has the top surfaces of the bearing bars notched. When the gratings are used in particularly wet environments or in places where extra non-slip properties are required, serrated bars will be an advantage. The serrating process involves carving a pattern in the bars to be serrated. This could be in either the control or filler bars or in both control and filler bars and bearing bars, depending on whether the grating needs serrating in one or both directions. Serration is available in two patterns: small serration and large serration. Small serration is the most commonly used serrating form, which is used for industrial walkway and staircase gratings etc. and for heavy duty ramp gratings. Large serration is very easy to clean and therefore primarily used in industrial kitchens, canteens and in other places with high hygiene requirements and requirements of non-slip properties. Serrated bearing bars and control and filler bars.

Optional serrated bearing bars enhance skid resistance. Consider this surface for applications subject to the accumulation of liquids or lubricants or inclined grating installations. The excellent self-cleaning characteristics of plain surface grating make it suitable for the majority of applications. In the presence of fluids or materials that could cause the top surface of the grating to become wet or slippery, specification of the optional serrated surface should be considered. When serrated gratingis specified, the bearing bar depth must be 1/4" greater, to provide the equivalent strength of non-serrated gratings.

1.Features:Ease of installationEconomicalHigh strength-to-weight ratio and light weightNo sharp edgesLow maintenance surfacesSerrated (slip resistant)High point load capabilities suitable for vehicular trafficHot rolled serrations help stop lacerations if someone falls on the gratingVentilation of air, light and soundDont collect liquid and debrisLong service lifeWide range of open areas

2.ApplicationAnti slip bridge deckingBridge walkwayDrainage systemFire truck platformMass transit platformMarine and ship deckMezzaninesNon-slip walkwayNon-skid pit coverSlip resistant platformGeneral IndustryTruck platformVault coverWet DeckWastewater treatment plant grating

3.Information:

1) the pitch of the grating between bearing bars is 30mm. It's most widely used typy in industrial field. Among notmal types, it has the strongest resistance to surface lash.

2) the pitch of steel grating between bearing bar is 40mm. It's the most economical and lightes type. It's the best choice for you on occasions that the clear span is small.

3) the pitch of the steel grating between bearing bar is 60mm and the pitch between cross bars is 50mm. It's developed specially for mining industry. It solves the problem of mineral splash on the plate. So it's often appointed to use in processing works of mining industry.

4) the pitch of the steel grating 30mm between bearing bars and 100mm between cross bars is the most popular type used home and abroad. It's proper for many applications such as walkways, platforms, etc.

Generally speaking,common specification:

Mesh size:30*50mm 60*50mm 60*100mm 30*100mm

Flat bar size :25*5 19*3mm

twisted bar(cross bar):6mm

Your requirement is available.

4.Material Description:All materials are of SS400 steel as stipulated in CNS and JIS specifications and are hot-dip galvanized subject to the regulation ofCNS1247. The tensile strength is 41-52kg/mm2, elongation 26% and above, and yield degree 22kg/mm2

5.Product Information:The 1/4" cross bars are electro-forge welded to the bearing bars by a patented process that combines hydraulic pressure and electric current. This welding process results in a strong, durable grating perfectly suited for a wide range of applications.

6.Welded Series:FW Grating's bar grating products are divided into four series. Each series has specific bearing and cross bar spacing, bearing bar sizes, weights, load characteristics, fastener requirements, etc. Links to welded bar grating series information are provided below:

7.Material Types:

Welded Bar Grating: Available in both Carbon Steel and Stainless SteelPress Locked Bar Grating: Available in Aluminum, Carbon Steel, Stainless SteelSwaged Bar Grating: Available in Stainless Steel8.Panel sizes available:

2' x 20'3' x 20'2' x 24'3' x 24'9.Panel surface options: Smooth, Serrated or Mebac™

10.Panel finish options:

Mill, Painted, Powder Coated or Galvanized

Both Light, Heavy Duty and ADA (American Disabilty Act) Bar Grating are available and in stock.

11.Uses:

Widely applied in the power plant, the chemical plant, the refinery, the iron and steel plant, the paper mill, the machine factory, the cement plant, the municipal engineering, sewage treatment plant, environmental sanitation project as platforms, the aisle, the trestle, the ditch lid, the well lid, the ladder, the railing, the guard rail and so on.

Steel Galvanized Grating